In order to guarantee product conformity with design specifications, BTS has implemented an efficient monitoring system. Our quality manager defines the method for checking product specifications during the manufacturing process as well as for running incoming and final tests. In compliance with these instructions, our suitably trained and skilled employees carry out checks in each phase of the manufacturing process including inspections on incoming materials.

In order to guarantee product conformity with design specifications, BTS has implemented an efficient monitoring system. Our quality manager defines the method for checking product specifications during the manufacturing process as well as for running incoming and final tests. In compliance with these instructions, our suitably trained and skilled employees carry out checks in each phase of the manufacturing process including inspections on incoming materials.

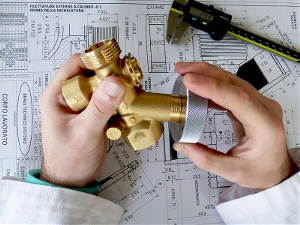

The BTS quality department is equipped with a wide range of measurement devices such as 3d coordinate measuring machines, profile projectors, roughness testers, micrometers, thread ring gauges and plugs, plan ring gauges and plugs.

Periodic checks and calibration of all measurement devices is a crucial step in guaranteeing reliability. We do it externally using accredited laboratories or internally using Masters certified SIT-NAMAS.

Upon request, any proof test or metallographic analysis can be performed using specialized labs.

All checks carried out on products are recorded and the reports are retained for 2 years. Control plans can be modified upon specific customer requests. Sample check plans and LQA are regulated by UNI EN ISO 2859.